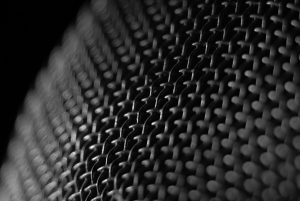

We are going to look into how the two common forms of wire mesh is formed. Welded mesh manufacturers can do a range of creations such as welded or woven mesh which will be discussed below. A common form of metal screen which comprises of parallel rows and intersecting columns of wire is called wire mesh. These converging wires are ordinarily combined by welding or weaving – two of the more typical forms of wire mesh. The solid wire used is often created by progressively drawing down a metal in a series of round dies until it reaches the desired diameter. Despite identical in appearance and their applications, perforated metal sheet and expanded metal sheet are not forms of wire mesh. Wire mesh comes in a relatively boundless measure of shapes and sizes, and an expansive assortment of materials and metal compounds.

Welded Wire Mesh

Welded wire mesh has intersecting lines and sections of parallel wires that are welded together at the convergence. As soon as the wire has been drawn right down to the preferred length, it’s fed into a machine that welds multiple rows of wire along at their intersection. As the mesh is sustained through the machine, a parallel line of welds is then formed at the same time wherever the perpendicular lines meet. The succeeding intersection of wires is then fed through the machine to be welded, and this method continues, becoming a member of every row of wires collectively. This device generally welds the wires using the electrical resistance as the source of heat. Even though other welding methods could be employed, this is the most cost-effective way. Once the mesh has reached the specified length, it is cut by a shear, resulting in a sheet of flat and rigid welded wire mesh.

Woven Wire Mesh

Just like a woven textile, the woven wire mesh has a variety of intersecting wires. Normally, the wires are woven over and underneath the opposite wires to create a steady sheet. This pattern is thought as a “Plain Weave Mesh”. While for applications that require a versatile sheet, a “Twill Weave” can be used. This involves wire that’s woven over a pair of perpendicular wires, then beneath consequent set of two perpendicular wires, and so on. Woven wire mesh doesn’t have welds on them. Rather, they are bolstered into a machine like a loom which encourages a straight wire through chosen weave design. The wires are then bent to the reverse position, and also the next straight wire is fed through the pattern. The machine proceeds with this technique till the specified measurements are achieved and the finished wire mesh sheet is cut into particular sizes.

Applications

Welded wire mesh and woven wire mesh are used in various fields which includes:

- Fences

- Sifters

- Grills

- Machine and equipment safety barricades

- Concrete reinforcement

- Shelves

- Cages

The finest welded wire meshes are used for a wide range of commercial applications. They’re used for both business and modern purposes. It’s structure of intertwined wires have intersections welded together at regular intervals to form equal gapping. Commonly, a welded mesh is formed through a resistance welding process wherein orthogonal wires are joined together. Automated CNC welding machines are used to get the exact specifications and the grid of live wires should be guided using a pattern board. There are numerous measurement configurations and wire spacing alternatives to personalize their designs. Here are the elements of welded wire mesh for industrial purposes:

Materials Used:

Welded wire mesh can be used in a number of settings to achieve a higher level of performance with regard to corrosion-resistance. Subsequently, they are ideally produced from plain steel, stainless steel, and pre-galvanized steel. The stainless steel is a great alternative that you can use if you are looking for a top-notch quality and security. Moreover, these meshes are often a product of using special alloys and weavable substances that’s built according to specifications. The first-rate types are 304-grade and 316-grade stainless-steel.

The Wire Spacing:

The standard wire spacing is 1” although you may opt to select custom welded wire in a spacing that fits your purpose. The Spacing of welded wire mesh is drawn by dimensions made from the center of 2 wires or measurement of gap between 2 wires.

The Wire Diameter:

The welded mesh is accessible in a wide selection of measurements and you can select the correct diameter based on your desired strength. When determining the wire diameter, it is accurate to use the decimal format rather than the gauge format.

The Edge Conditions:

In a wire mesh, it’s classified under 2 basic types of edges known as trimmed and untrimmed wire mesh. As for trimmed mesh, there has to be right spacing across the border. This border can likewise be adjusted or lessened to remain inside the expected measurements. When checking for untrimmed edges, you should prefer outer wire overhanging that must be proportionate to the wire mesh spacing. In these meshes, tail length can likewise be custom-made according to customer specifications.

Standard Back Gain:

It is a characteristic event caused as a result of cooling and hearing the mesh. It’s commonly seen in tightly spaced wire mesh.

Quality Testing Procedures:

To help create the consistency of a welded wire mesh, manufacturers should follow rigorous internal standards, just like in steel fabrication dandenong. Several diverse quality measures are used to test the mesh’s dimension and strength, which then is documented throughout the assembly method using torque test and weld set-down mesh.

Aside from these, manufacturers must consider the factors involving the selection of these meshes by following the proper maintenance and safety protocols to ensure the durability of the wire mesh. Manufacturers also need to take into account whether they will need crane hire companies or frannas to transport the mesh panels from one location to the next, or for/to a building site.